In the domain of assembling and designing, Die Casting Mold assumes an urgent part in the creation of high-accuracy parts. These molds are crucial apparatuses that guarantee the formation of perplexing, exact, and sturdy parts utilized across different businesses. This article dives into the basic parts of Die Casting Mold, investigating their importance, benefits, and the reasons they are key for high-accuracy parts.

Die Casting Mold

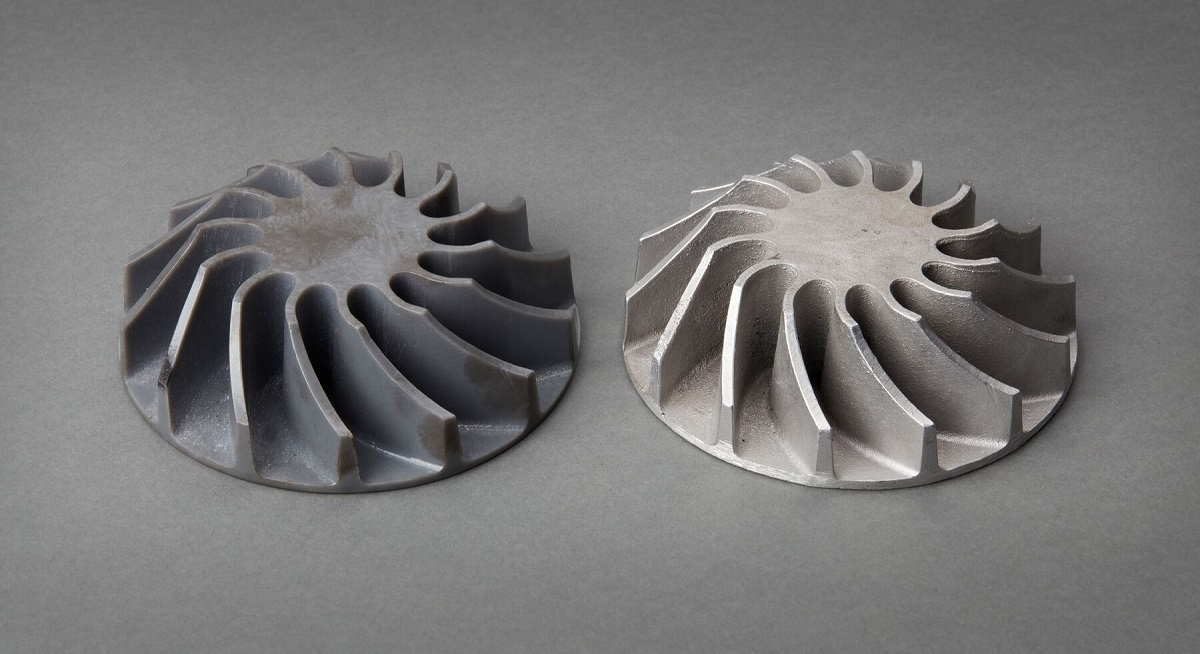

Die Casting Mold are intended to create metal parts plastic mold by infusing liquid metal into a hole under high tension. The cavity is formed by the ideal part’s determinations, and the shape’s accuracy straightforwardly impacts the quality and exactness of the eventual outcome. These molds are designed to endure high temperatures and tensions, making them fundamental for assembling parts with tight resiliences and complex calculations.

Kinds of Kick the bucket Projecting Molds

Cold Chamber Die Casting Mold

Cold chamber Die Casting Mold are utilized plastic mold metals with high softening places, like aluminum, magnesium, and copper combinations. In this cycle, the liquid metal is filled a virus chamber prior to being infused into the form pit. This kind of shape is great for applications that require high-strength materials and protection from mileage.

Hot Chamber Kick the bucket Projecting Molds

Hot chamber Die Casting Mold are utilized for metals with lower liquefying focuses, similar to zinc, lead, and tin amalgams. The metal is kept liquid in a supply and infused straightforwardly into the shape pit. This technique offers quicker process durations and is appropriate for high-volume creation of little to medium-sized parts.

Advantages of Kick the bucket Projecting Molds

Kick the bucket projecting molds give various benefits, pursuing them a favored decision for makers looking for top notch and savvy arrangements.

1. Predominant Accuracy and Exactness

One of the main advantages of Die Casting Mold is their capacity to deliver leaves behind uncommon accuracy and precision. The high-pressure infusion process guarantees that even many-sided subtleties and fine elements are duplicated with insignificant deviations. This degree of accuracy is essential for ventures like aviation, auto, and hardware, where tight resistances are obligatory.

2. Improved Solidness and Strength

Die Casting Mold are intended to deliver leaves behind upgraded sturdiness and strength. The high strain under which liquid metal is infused brings about a thick, cemented structure that opposes breaking, distorting, and misshapening. This toughness makes pass on cast parts appropriate for high-stress applications and brutal conditions.

3. Savvy Creation

Albeit the underlying expense of making a pDie Casting Mold can be high, the drawn out money saving advantages are huge. Die Casting Mold offer high creation rates and low per-unit costs because of their capacity to deliver huge amounts of parts rapidly and productively. Moreover, the decreased requirement for optional machining and completing cycles adds to by and large cost investment funds.

4. Complex Calculations and Dainty Walls

Die Casting Mold succeed at creating leaves behind complex calculations and flimsy walls. The high-pressure infusion process fills unpredictable form pits and catches fine subtleties, making it conceivable to make leaves behind intricate shapes and flimsy segments without compromising strength or uprightness. This ability is fundamental for delivering stylish parts and useful parts with cutting edge plans.

Uses of Die Casting Mold

Die Casting Mold are utilized across different ventures, each profiting from their one of a kind properties and benefits.

1. Car Industry

In the car area, Die Casting Mold are utilized to produce basic parts, for example, motor blocks, transmission lodgings, and brake parts. The accuracy and solidness of kick the bucket cast parts guarantee dependable execution and wellbeing in auto applications.

2. Aeronautic trade

The avionic business depends on Die Casting Mold to deliver lightweight and high-strength parts for airplane and rocket. Parts like motor housings, landing gear parts, and underlying components benefit from the high accuracy and protection from outrageous circumstances given by Die Casting Mold.

3. Customer Gadgets

In the customer gadgets industry, Die Casting Mold are utilized to make nooks, lodging parts, and mechanical parts for gadgets, for example, cell phones, tablets, and workstations. The capacity to deliver leaves behind fine subtleties and high stylish quality is essential for purchaser hardware.

4. Modern Apparatus

Die Casting Mold are likewise used to produce parts for modern apparatus and gear. Parts like gearboxes, siphons, and valves benefit from the strength and accuracy of bite the dust cast parts, guaranteeing dependable activity and long assistance life.

Plan Contemplations for Die Casting Mold

To accomplish ideal outcomes with Die Casting Mold, a few plan contemplations should be considered.

1. Shape Material

Choosing the fitting material for the pass on projecting mold is basic for its exhibition and life span. Normal materials incorporate device steel, heat-safe compounds, and carbide. The decision of material influences the form’s solidness, heat obstruction, and generally speaking expense.

2. Cooling Frameworks

Proficient cooling frameworks are fundamental for keeping up with the nature of bite the dust cast parts. Appropriate cooling guarantees uniform cementing of the liquid metal, limiting imperfections like shrinkage and twisting. Cooling channels and temperature control frameworks are vital to the plan of kick the bucket projecting molds.

3. Discharge Systems

Viable launch systems are important for eliminating the kick the bucket cast parts from the shape without causing harm. Different discharge frameworks, including pins, plates, and air impacts, are utilized to guarantee smooth and proficient part expulsion.

4. Resistances and Surface Completions

Planning Die Casting Mold with exact resistances and surface completions is fundamental for accomplishing the ideal nature of the last parts. Itemized thought of layered exactness, surface, and separating lines guarantees that the bite the dust cast parts satisfy details and stylish guidelines.

Upkeep and Care of Die Casting Mold

Normal support and care of kick the bucket projecting molds are significant for guaranteeing their ideal presentation and expanding their life expectancy.

1. Cleaning and Investigation

Routine cleaning and review of Die Casting Mold help distinguish and resolve issues like wear, erosion, and defilement. Ordinary support timetables and preventive measures guarantee that molds work at top effectiveness.

2. Fix and Repair

Over the long haul, Die Casting Mold might require fix and repair to address wear and harm. Proficient fix administrations and repair strategies can reestablish the shape’s exhibition and broaden its administration life.

3. Legitimate Capacity

Legitimate capacity of kick the bucket projecting molds when not being used forestalls harm and corruption. Environment controlled capacity and defensive measures guarantee that molds stay in ideal condition.

Kick the bucket projecting molds are principal to the development of high-accuracy parts, offering unrivaled benefits concerning precision, solidness, and cost-viability. Their application across different ventures features their fundamental job in current assembling.

Summary

Die Casting Mold are significant for creating high-accuracy parts across different enterprises. They work by infusing liquid metal into a pit under high tension, guaranteeing the formation of perplexing and precise parts. There are two principal sorts of kick the bucket projecting molds: cold chamber and hot chamber, each appropriate for various metal composites and creation needs. The advantages of utilizing Die Casting Mold incorporate prevalent accuracy, upgraded strength, cost-viability, and the capacity to create complex calculations with flimsy walls. They are generally utilized in areas, for example, car, aviation, buyer hardware, and modern apparatus. Key plan contemplations for Die Casting Mold incorporate material determination, cooling frameworks, launch components, and resilience levels. Customary support, cleaning, and legitimate stockpiling are fundamental for expanding the life expectancy and guaranteeing ideal execution of Die Casting Mold. By and large, Die Casting Mold molds are fundamental devices for assembling superior grade, exact, and strong aspects.